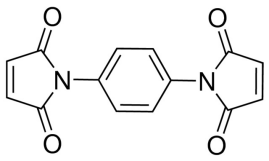

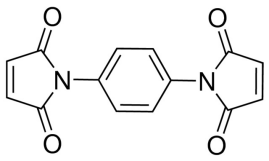

Rubber vulcanizing agent -N,N'-m-phenylene dimaleimide , manufactured by Yangchen Tech as a multifunctional rubber additive, plays a role as vulcanizing agent, co-vulcanizing agent, anti-scorch agent and extender in the rubber processing process. Various functions such as adhesives can improve the performance and quality of rubber products and meet different rubber systems and processing needs.

Technical indicators:

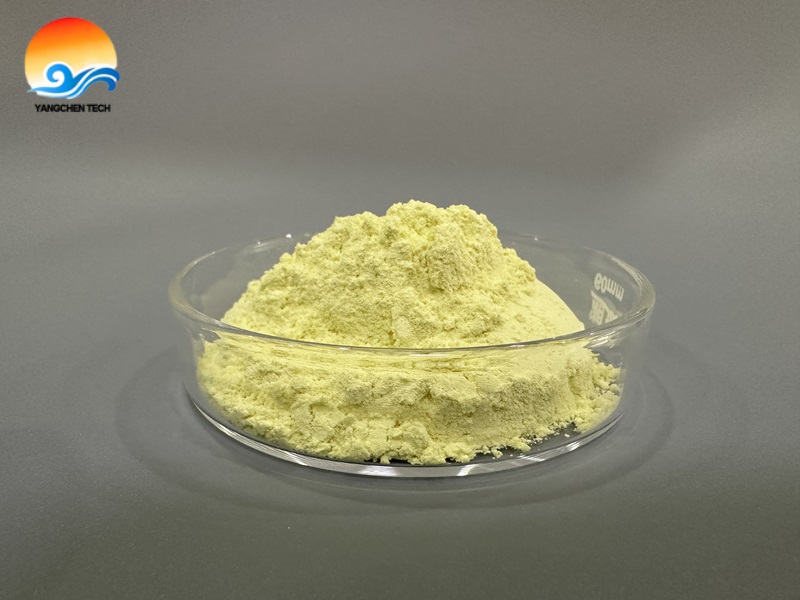

| Appearance |

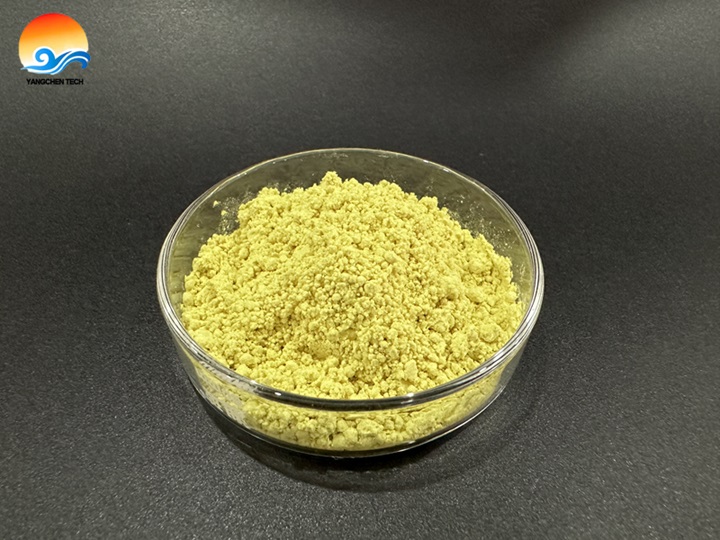

Yellow powder |

| Melting point |

≥196℃ |

| Moisture content |

≤0.5% |

| Ash content |

≤0.5% |

Application

Rubber vulcanizing agent -N,N'-m-phenylene dimaleimide manufactured by Yangchen Tech can be used in different rubber systems:

1.Vulcanizing agent: PDM can be used as a vulcanizing agent to participate in the vulcanization reaction during rubber processing. Vulcanization is a key step in rubber processing. Through the vulcanization reaction, linear rubber molecular chains form a cross-linked structure, thereby improving the physical and mechanical properties of rubber products, such as tensile strength, wear resistance, aging resistance, etc.

2.Assisting vulcanizing agent: In addition to being a vulcanizing agent, PDM can also be used as an assisting vulcanizing agent in peroxide systems. In the peroxide vulcanization system, PDM can promote the vulcanization reaction and accelerate the cross-linking process of rubber, thereby improving the performance of vulcanized products.

3.Anti-scorch agent: During rubber processing, due to high temperature or long-term heating, rubber is prone to scorch, resulting in a decline in product quality. As an anti-scorch agent, PDM can effectively inhibit the early vulcanization of rubber, that is, scorch, thereby extending the safe processing time of rubber and improving the quality of products.

4.Tackifier: PDM also has a tackifier effect, which can increase the viscosity of rubber. In the production process of rubber products, tackifiers can increase the adhesion between rubber and other materials (such as fibers, metals, etc.) and improve the bonding strength of the products.

5.Applicable to a variety of rubber systems: PDM is not only suitable for general rubber, such as natural rubber, styrene-butadiene rubber, etc., but also for special rubber and rubber-plastic systems. This gives PDM a wider range of applications in the rubber industry.

Dosage: 0.5-1.0 phr as vulcanization retarder. 2-3 phr as a vulcanizer. 1.5 phr to improve compression distortion. 0.5-5.0 phr to increase adhesive strength.

If you have any questions or need us to provide technical service support,pls feel free to contact: business@xysjgm.com

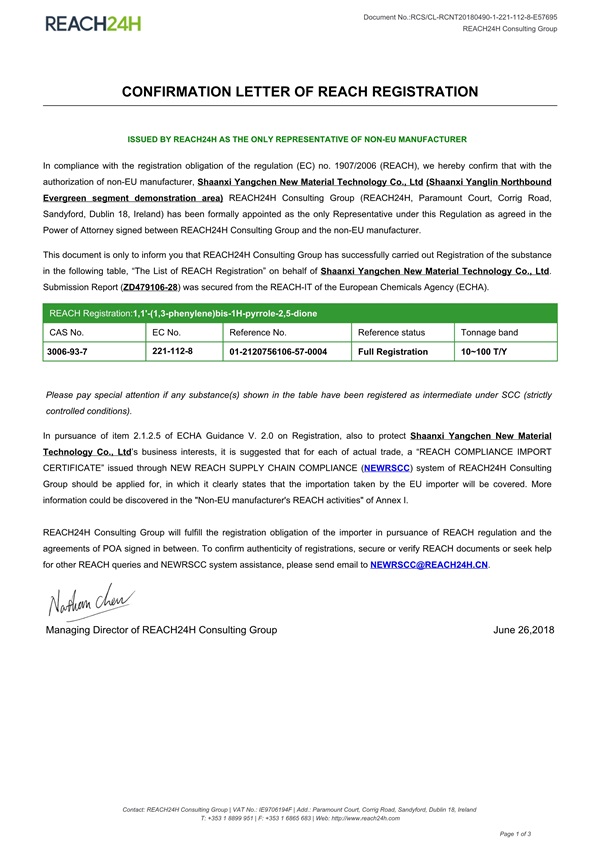

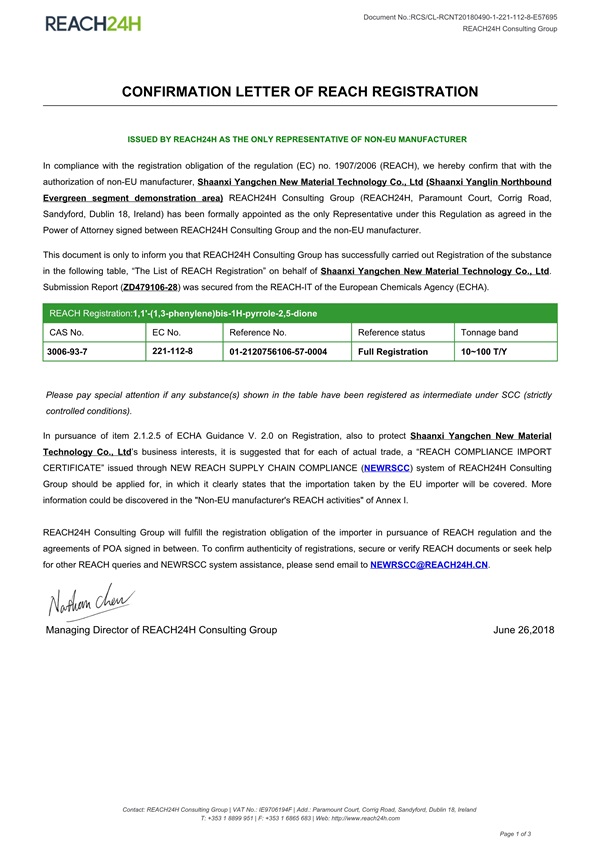

Reach24H certification

Our warehouse

Manufacturing Workshop of Yangchen Tech

Why choose Yangchen Tech?

1.We are the first competent factory manufacturing N,N'-m-phenylene bismaleimide in China, with an annual production capacity of 350 tons.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

If you have any questions,pls feel free to contact: business@xysjgm.com

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are the first HVA-2 manufacturer in China, with an annual production capacity of 350 tons.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message