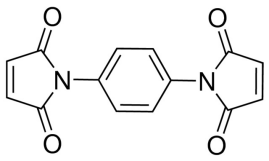

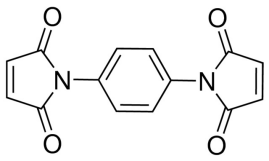

Product Name: N,N'-m-phenylene bismaleimide

Other Name:N,N'-1,3-Phenylenedimaleimide / N,N'-1,3-Phenylene bismaleimide / m-Dimaleimidobenzene / m-Phenylenedimaleimide

Abbreviation: HA-8 / HVA-2 / PDM

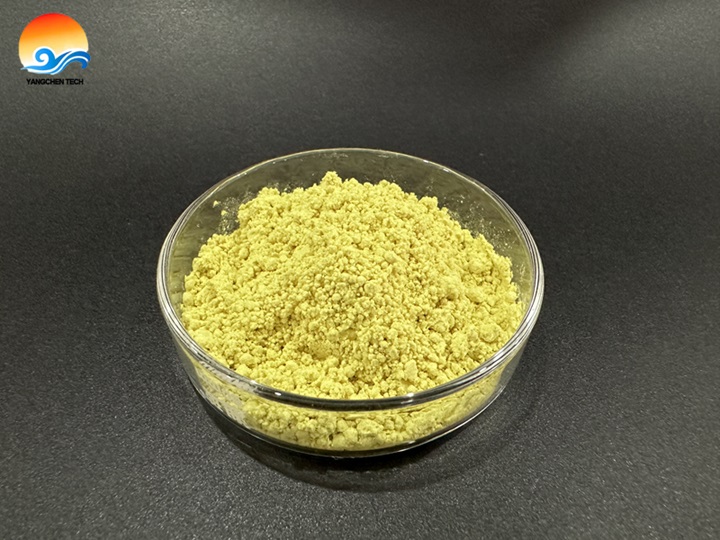

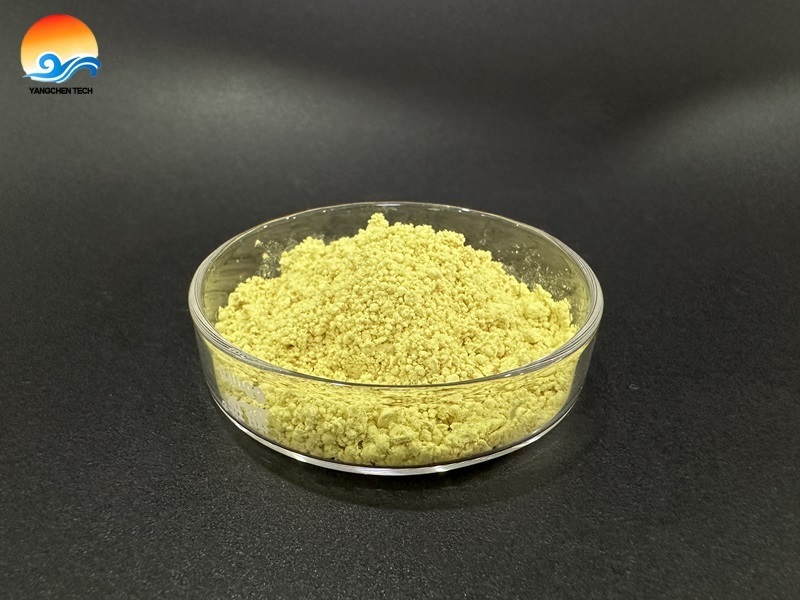

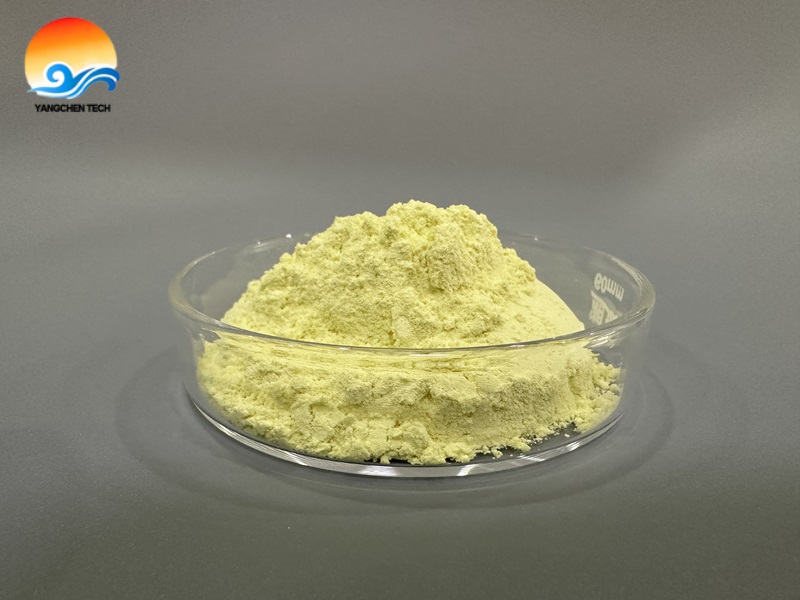

Properties: It is a yellow or brown powder, soluble in dioxane, tetrahydrofuran and hot acetone, but insoluble in petroleum ether, chloroform, benzene and water.

-

-

-

HVA-2 powder

Whatever you needs, Yangchen Tech is at your side.

Certifiction of Analysis

|

Product Name

|

N,N'-m-phenylenedimaleimide(HA-8/HVA-2/PDM)

|

|

Property

|

Limits

|

Results

|

|

Form

|

Free Flowing Powder

|

Free Flowing Powder

|

|

Color

|

Yellow to light Brown

|

Yellow

|

|

Contamination

|

None

|

None

|

|

Melting Range℃

|

≥195

|

201.8

|

|

Water %

|

≤ 0.5

|

0.02

|

|

Ash %

|

≤ 0.3

|

0.01

|

|

Oil %

|

≤5

|

3.1

|

|

Acidity mgkoH/g

|

≤5

|

1.1

|

|

Particle Size

On 100 mesh %

On 325 mesh %

|

0.0Max

0.5Max

|

0

0

|

Function and cooperation:

N,N'-1,3-Phenylenedimaleimide(HA-8/HVA-2/PDM) is a versatile rubber additive used as a vulcanizing agent in rubber processing and peroxide systems. It serves as an anti-scorch agent and tackifier, suitable for general-purpose and special rubbers like neoprene, chlorosulfonated polyethylene rubber, styrene-butadiene rubber, nitrile rubber, isoprene rubber, butyl rubber, bromobutyl rubber, acrylic rubber, silicone rubber, and rubber-plastic composites.

As an auxiliary vulcanizing agent, HA-8 enhances cross-linking properties and heat resistance, ideal for high-temperature vulcanization systems. It reduces compression permanent deformation, minimizes peroxide usage, prevents scorching during processing, and improves bonding strength between rubber and skeleton materials. Additionally, it resolves issues like copper sulfide pollution and blackening from sulfur-containing vulcanizing agents in copper-related applications.In the adhesive industry, HA-8 acts as a heat-resistant modifier, particularly in anaerobic adhesives, enhancing product temperature resistance effectively.

Dosage: As an anti-scorch agent: 0.5-1.0 parts. As a vulcanizing agent, it is 2-3 parts, to improve compression deformation is 1.5 parts, to improve bonding strength is 0.5-5.0 parts, and in adhesives it is 5-10 parts.

Packaging:

PE bag lined with PE film, net weight 10kg or 25kg cardboard drum.

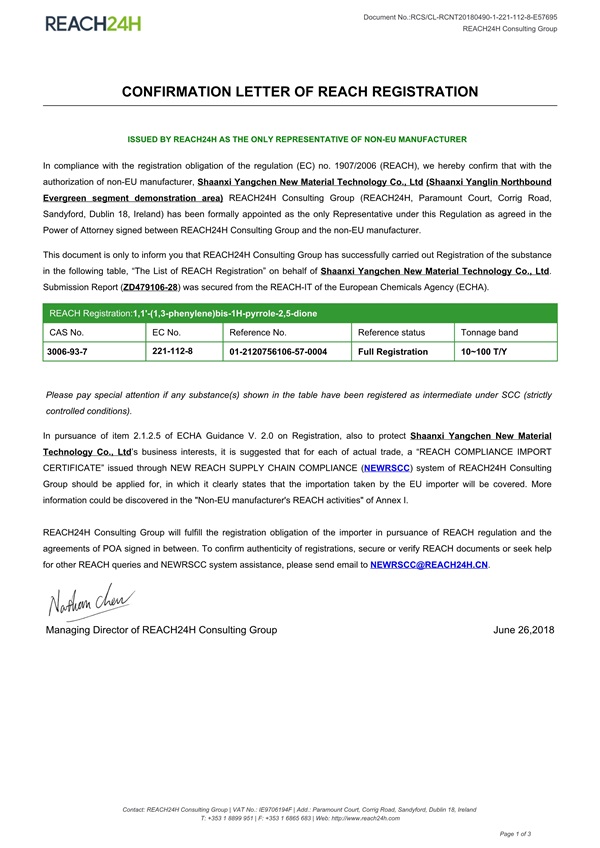

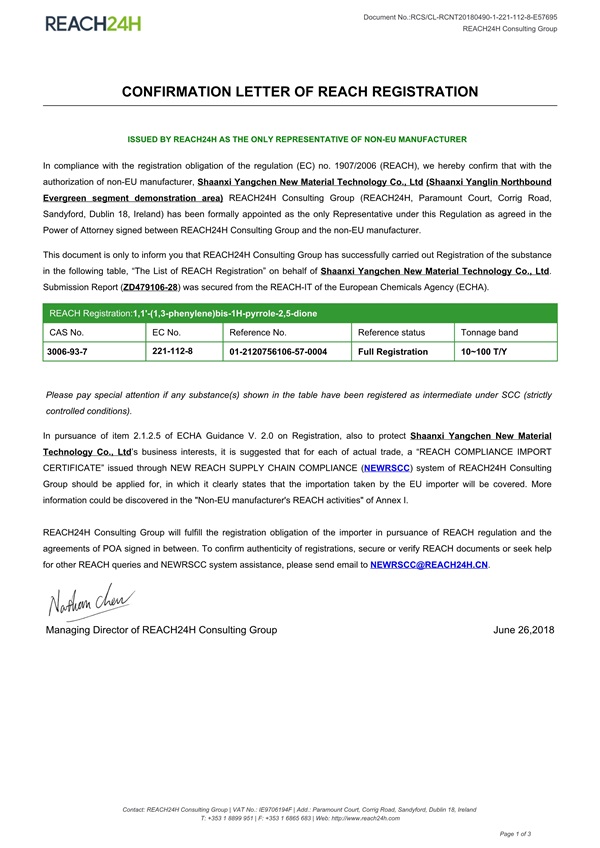

Reach24H certification

N,N'-m-phenylene bismaleimide products we manufacture have obtained REACH certification, and we specialize in bismaleimide products fields.

Application

1.In natural rubber, N,N'-m-phenylene bismaleimide with sulfur can prevent the return of vulcanization, improve the heat resistance of rubber, reduce heat generation, as well as aging resistance, and at the same time, it also improves the adhesion between rubber and cords and the modulus of vulcanized rubber. Used in shoulder rubber of loaded tires, cushion layer and other rubbers, it can solve the problem of shoulder emptying of bias loaded tires, and can also be used in large-size and thick products of natural rubber and all kinds of rubber miscellaneous products.

2.In neoprene rubber, chlorosulfonated polyethylene rubber, styrene butadiene rubber, nitrile rubber, isoprene rubber, butyl rubber, bromobutyl rubber, acrylate rubber, silicone rubber and rubber-plastic rubber and other special rubbers, as an auxiliary vulcanizing agent, it can significantly improve the crosslinking performance, improve heat resistance, suitable for high temperature vulcanization system, reduce the permanent deformation of the compression is very obvious, but also reduce the dosage of peroxides, to prevent rubber from burning during processing. It can also reduce the amount of peroxide, prevent the rubber from burning in the process, and improve the adhesive strength of rubber, cord and metal.

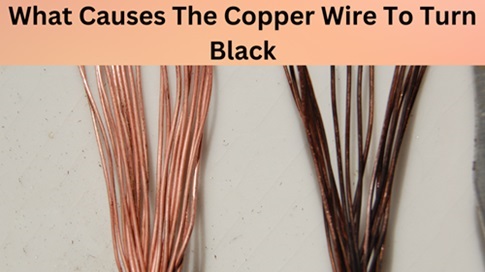

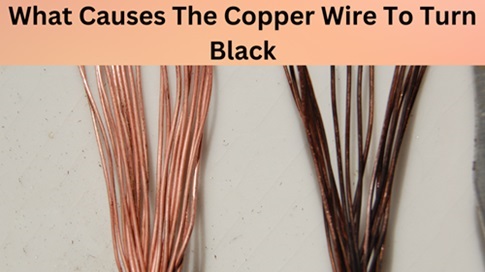

3.N,N'-m-phenylene bismaleimide is a non-sulfur vulcanizing agent, which can be used for cable rubber. It can replace all sulfur-containing vulcanizing agents such as thiazole, thiuram, etc. It solves the problem of blackening of copper conductors and copper electrical appliances due to contact with sulfur-containing vulcanizing agents to generate copper sulfide contamination.

Manufacturing Workshop of Yangchen Tech

Why choose Yangchen Tech?

1.We are the first competent factory manufacturing N,N'-m-phenylene bismaleimide in China, with an annual production capacity of 3500 tons.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are the first HVA-2 manufacturer in China, with an annual production capacity of 3500 tons.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message