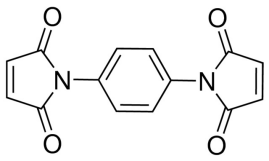

Product Name: N,N'-1,3-Phenylenedimaleimide

CAS NO:3006-93-7

Abbreviation:HA-8 / HVA-2 / PDM

Application: Crosslinking agent / Tire vulcanizing agent

Any questions ,pls feel free to contact:business@xysjgm.com,we can provide free sample for your testing.

Certifiction of Analysis

|

Product Name

|

N,N'-m-phenylenedimaleimide(HA-8)

|

|

Property

|

Limits

|

Results

|

|

Form

|

Free Flowing Powder

|

Free Flowing Powder

|

|

Color

|

Yellow to light Brown

|

Yellow

|

|

Contamination

|

None

|

None

|

|

Melting Range℃

|

≥195

|

201.8

|

|

Water %

|

≤ 0.5

|

0.02

|

|

Ash %

|

≤ 0.3

|

0.01

|

|

Oil %

|

≤5

|

3.1

|

|

Acidity mgkoH/g

|

≤5

|

1.1

|

|

Particle Size

On 100 mesh %

On 325 mesh %

|

0.0Max

0.5Max

|

0

0

|

Functions:

N,N'-1,3-Phenylenedimaleimide (HA-8/HVA-2/PDM) manufactured by Yangchen Tech is a versatile rubber additive used as a tire vulcanizing agent in rubber processing and peroxide systems. It functions as an anti-scorch agent and tackifier, suitable for various rubbers including neoprene, chlorosulfonated polyethylene rubber, styrene-butadiene rubber, nitrile rubber, isoprene rubber, butyl rubber, bromobutyl rubber, acrylic rubber, silicone rubber, and rubber-plastic composites.

As an auxiliary vulcanizing agent, HA-8 improves cross-linking properties and heat resistance, making it ideal for high-temperature vulcanization systems. It reduces compression permanent deformation, lowers peroxide usage, prevents scorching during processing, and enhances bonding strength between rubber and skeleton materials. Moreover, it addresses concerns such as copper sulfide pollution and blackening caused by sulfur-containing tire vulcanizing agents in copper-related applications. In the adhesive industry, HA-8 serves as a heat-resistant modifier, especially in anaerobic adhesives, effectively enhancing product temperature resistance.

Application on tires:

N,N'-1,3-phenylene dimaleimide (PDM) manufactured by Yangchen Tech is a specific type of maleimide compound used as a tire vulcanizing or cross-linking agent in tire manufacturing. To improve the mechanical properties, durability and heat resistance of the rubber compound, thereby increasing the performance and service life of the tire.

Cross-linking agent: PDM can be incorporated into the rubber compound used in tire manufacturing as a tire cross-linking agent during the vulcanization process. In tire production, natural or synthetic rubber compounds are often reinforced with fillers and additives to improve their properties. During the vulcanization process, these rubber compounds are exposed to heat and pressure, causing them to cross-link and form a three-dimensional network structure that enhances the rubber's mechanical properties and durability.

Improves tire performance: Adding PDM as a tire cross-linking agent helps improve the performance characteristics of tires. It enhances the rubber's tensile strength, tear resistance and abrasion resistance, making the tire more durable and able to withstand the stresses and strains encountered during normal use.

Enhanced heat resistance: PDM can also improve the heat resistance of the compound, helping the tire maintain its integrity and performance at high temperatures. This is especially important for tires driven at high speeds or heavily loaded, as heat buildup can accelerate tire wear and degradation.

Optimize tire performance: The use of PDM enables tire manufacturers to fine-tune the properties of rubber compounds to meet specific performance requirements. By adjusting the formulation and concentration of PDM, tire manufacturers can tailor the tire's stiffness, flexibility and other properties to optimize performance in different applications such as passenger cars, commercial trucks or racing cars.

N,N'-1,3-Phenyldimaleimide (PDM) is used as a tire vulcanizing agent in tire manufacturing to improve the mechanical properties, durability and heat resistance of rubber compounds, thereby improving tire performance and usage life.

Dosage: As an anti-scorch agent: 0.5-1.0 parts. As a vulcanizing agent, it is 2-3 parts, to improve compression deformation is 1.5 parts, to improve bonding strength is 0.5-5.0 parts, and in adhesives it is 5-10 parts.

N,N'-m-phenylene bismaleimide products we manufacture have obtained REACH certification, and we specialize in bismaleimide products fields.

Packaging:

PE bag lined with PE film, net weight 10kg or 25kg cardboard drum.

Manufacturing Workshop of Yangchen Tech

Why choose Yangchen Tech?

1.We are the first competent factory manufacturing N,N'-m-phenylene bismaleimide in China, with an annual production capacity of 350 tons.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

If you have any questions,pls feel free to contact: business@xysjgm.com

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are the first HVA-2 powder manufacturer in China, with an annual production capacity of 350 tons.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message