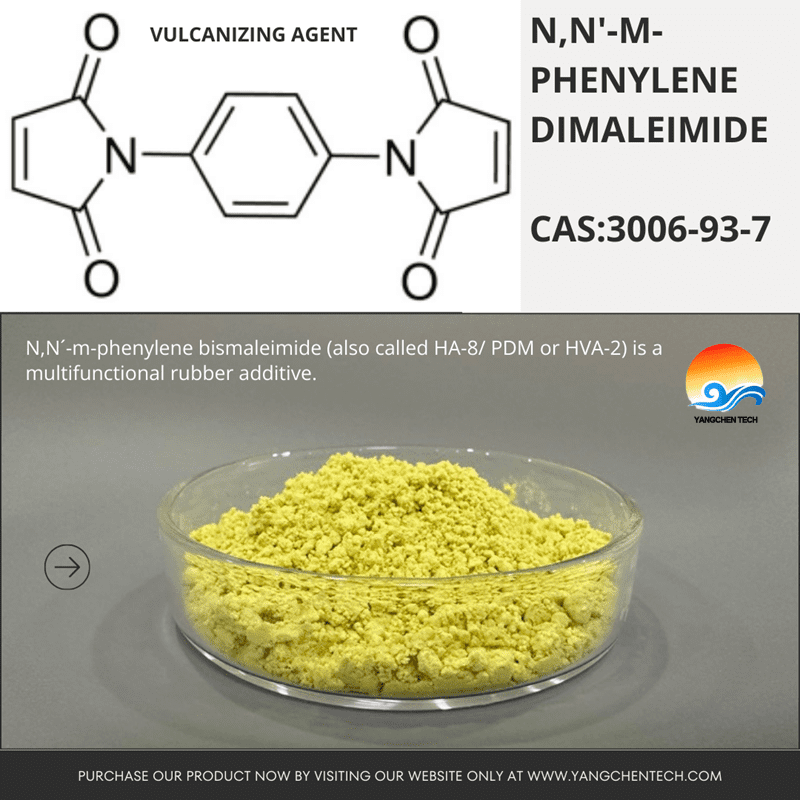

Technical indicators:

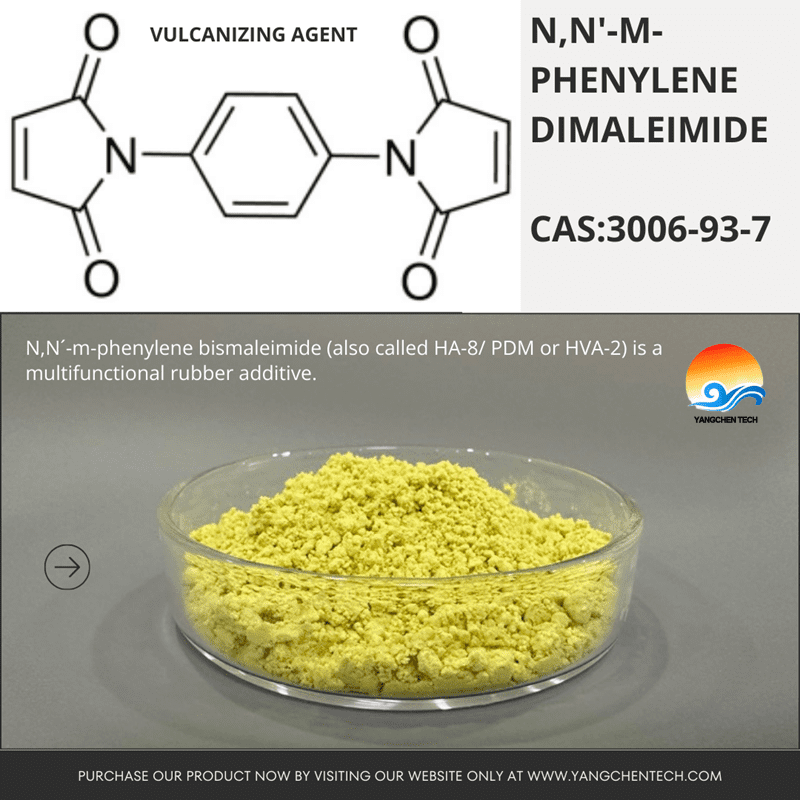

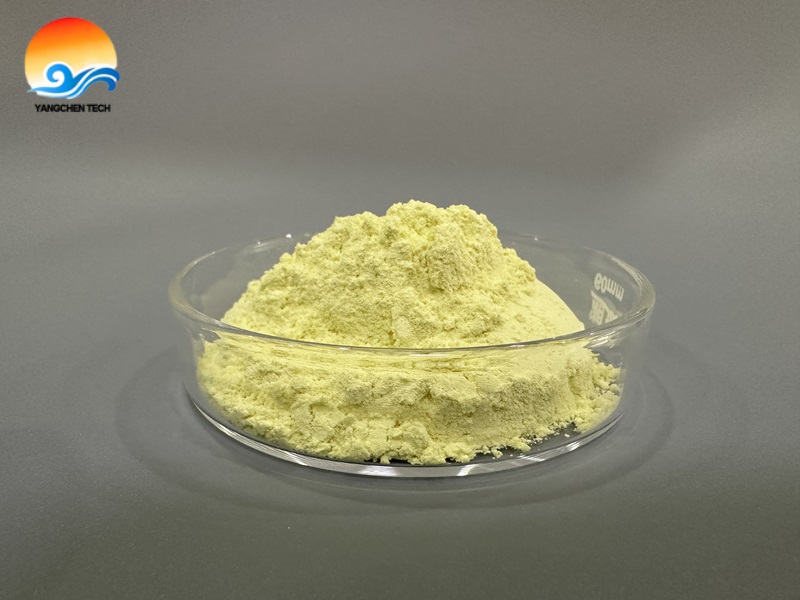

| Appearance |

Yellow powder |

| Melting point |

≥196℃ |

| Moisture content |

≤0.5% |

| Ash content |

≤0.5% |

During rubber processing, HA-8 is mainly used as a cross-linking agent. It forms a three-dimensional network structure through an addition reaction with the double bonds in the rubber molecular chain, thereby significantly improving the physical properties and chemical stability of rubber products. Specifically, the impact of the addition of Crosslinking agent on the rubber processing process and final products is mainly reflected in the following aspects:

1.Increase the vulcanization rate and cross-linking density: The bismaleimide group in N,N'-m-phenylene dimaleimide can quickly vulcanize with the unsaturated bonds in the rubber, significantly increasing the vulcanization rate of the rubber. At the same time, due to the addition of N,N'-m-phenylene dimaleimide, the number of cross-linking points between rubber molecular chains increases and the cross-linking density increases, which significantly improves the mechanical strength, wear resistance and aging resistance of rubber products.

2. Improve thermal stability and heat resistance: Crosslinking agent-N,N'-m-phenylene dimaleimide itself has excellent heat resistance, and its addition to rubber can significantly improve the thermal stability of rubber products. In high temperature environments, rubber products are not prone to softening or deformation, and can maintain good dimensional stability and mechanical properties.

3. Improve electrical insulation: Crosslinking agent- N,N'-m-phenylene dimaleimide is an excellent electrical insulation material. Adding rubber can significantly improve the electrical insulation properties of rubber products. This has important application value for rubber products that require high electrical insulation properties, such as wire and cable insulation layers, electrical equipment seals, etc.

4. Enhance chemical resistance: The chemical stability of Crosslinking agent- N,N'-m-phenylene dimaleimide enables it to maintain stable performance in a variety of chemical media. Therefore, rubber products added with N,N'-m-phenylene dimaleimide have better chemical corrosion resistance and can maintain stable performance for a long time in harsh environments such as acids and alkalis.

5. Improve processing performance: Adding an appropriate amount of N,N'-m-phenylene dimaleimide can also improve the processing performance of rubber. During the rubber mixing process, HA-8 can form a good dispersion system with rubber and other compounding agents, improve the fluidity and plasticity of rubber, and is beneficial to the molding and processing of rubber products.

It should be noted that the amount of Crosslinking agent-N,N'-m-phenylene dimaleimide should be controlled within a certain range. Too much or too little may have an adverse effect on the performance of rubber products. At the same time, it is also necessary to pay attention to the compatibility and synergy between HA-8 and other compounding agents during rubber processing to ensure the optimal performance of rubber products.

N,N'-m-phenylene dimaleimide has a significant promoting effect during rubber processing and can significantly improve the physical properties, chemical stability and processing performance of rubber products. Its application requires reasonable formula design and process control based on specific product requirements and production conditions.

Dosage: 0.5-1.0 phr as vulcanization retarder. 2-3 phr as a vulcanizer. 1.5 phr to improve compression distortion. 0.5-5.0 phr to increase adhesive strength.

If you have any questions or need us to provide technical service support,pls feel free to contact: business@xysjgm.com

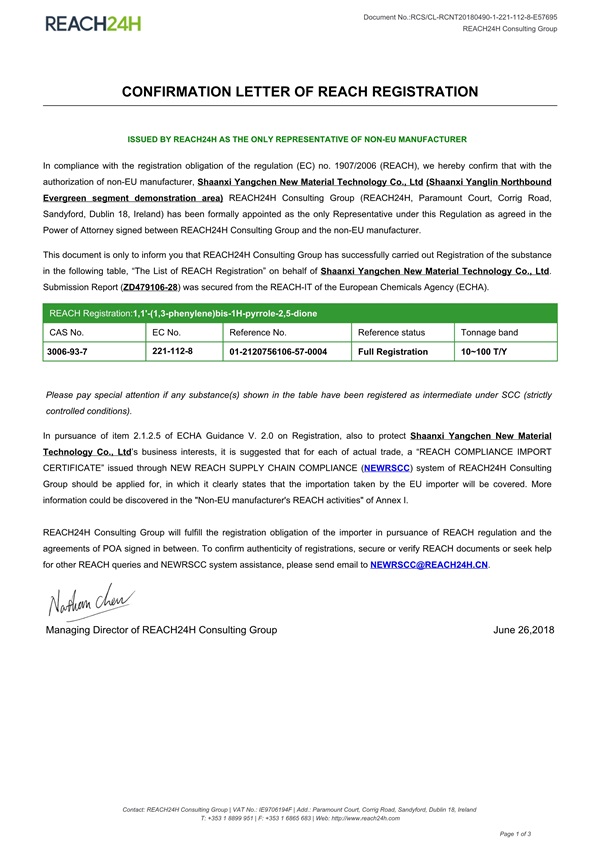

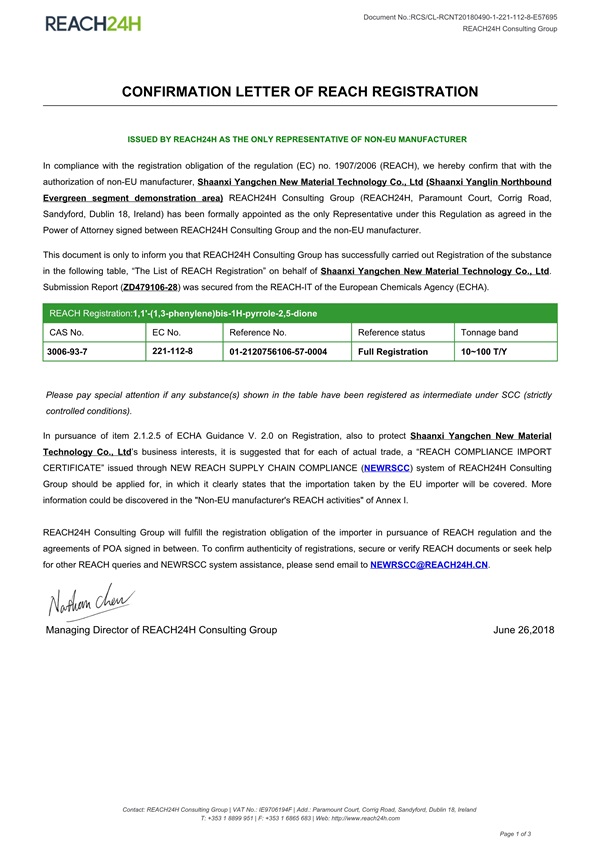

Reach24H certification

Our warehouse

Manufacturing Workshop of Yangchen Tech

Why choose Yangchen Tech?

1.We are the first competent factory manufacturing N,N'-m-phenylene bismaleimide in China, with an annual production capacity of 350 tons.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

If you have any questions,pls feel free to contact: business@xysjgm.com

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are the first HVA-2 manufacturer in China, with an annual production capacity of 350 tons.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message