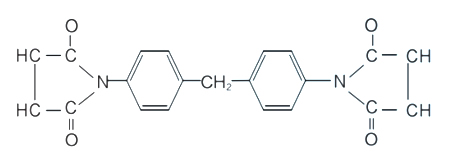

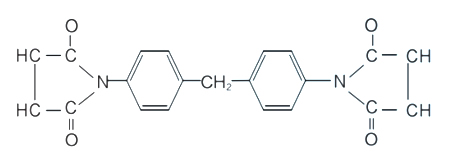

N,N-4,4-diphenylmethyene bismaleimide (BMI or BDM for short) is a chemical substance also known as N,N'-4,4'-diphenylmethane bismaleimide. Its molecular formula is C21H14N2O4 and its molecular weight is 358.37.

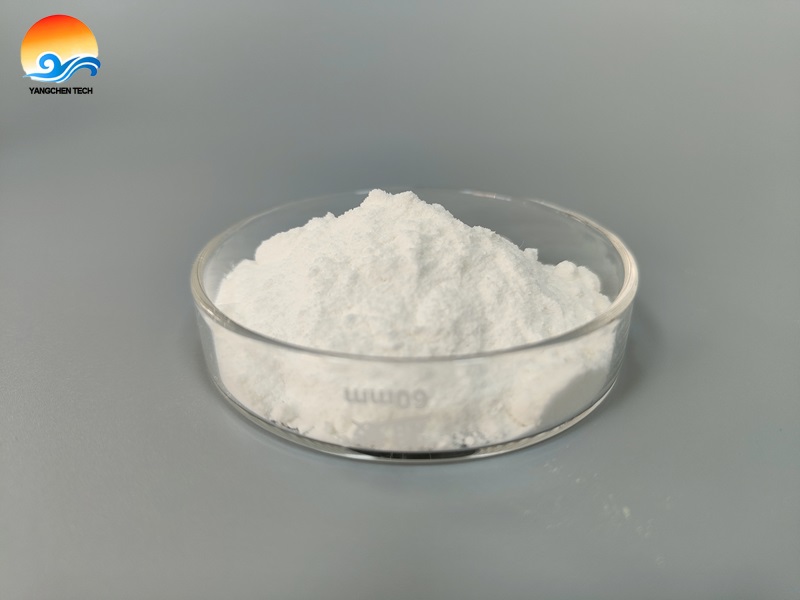

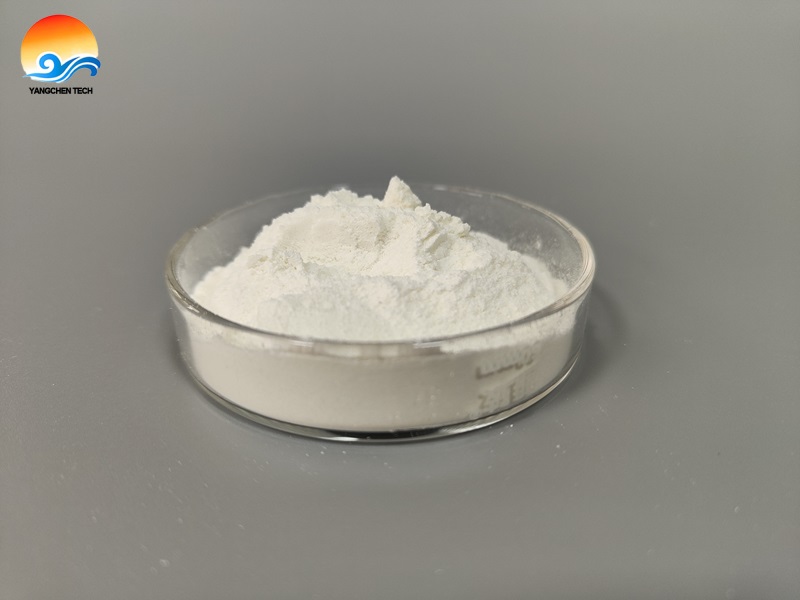

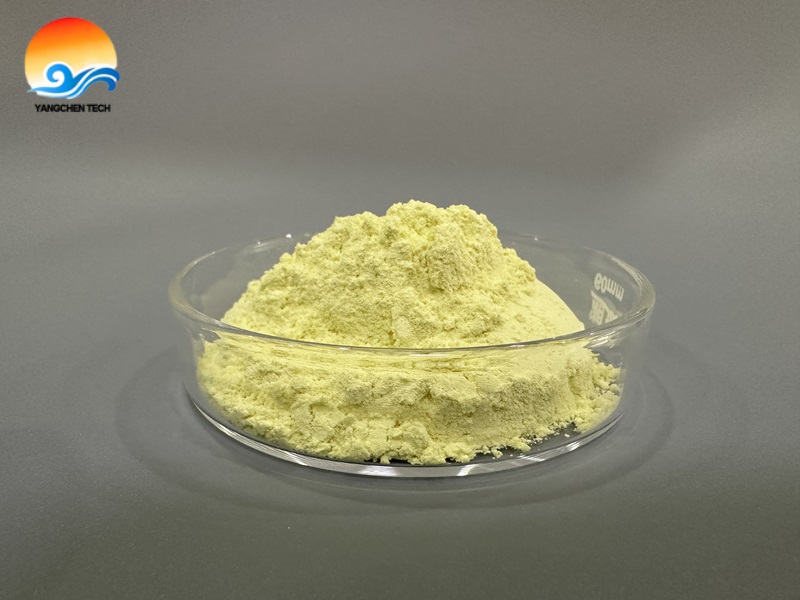

BMI is a light yellow solid powder with a melting point of 150-158°C. It is difficult to dissolve in water and ethanol, but is easily soluble in organic solvents such as acetone and dimethylformamide.

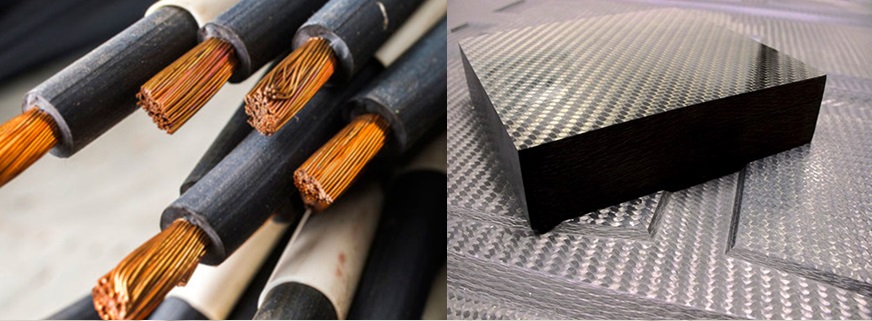

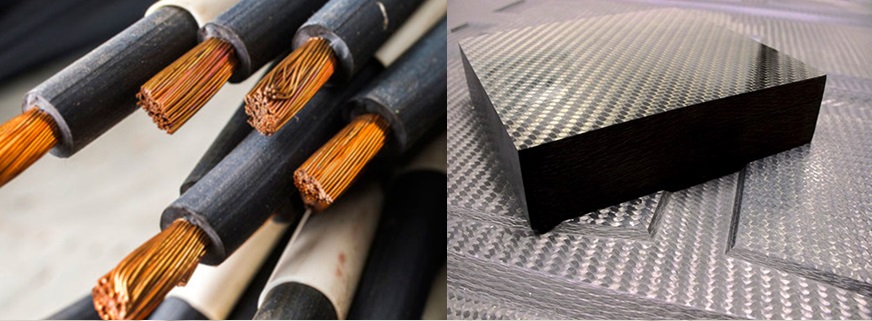

BMI manufactured by Yangchen Tech is an important raw material, mainly used in the manufacture of bima resin modified phenolic resin. This modified phenolic resin has excellent heat resistance, mechanical properties, insulation properties and chemical stability, so it is widely used in aerospace, electronics, automobile manufacturing and other industrial fields. Special resin basic composite materials produced with BMI as raw materials include heat-resistant circuit boards, motor insulating paint, carbon fiber high-temperature and wear-resistant materials, brake discs, wear-resistant grinding wheels, etc.

Technical Indicators

| Appearance |

Melting point |

Acid value |

Volatile

|

Specification |

Gel time |

Toluene Solubility |

| Yellow powder |

150-160℃ |

≤1mgKOH/g

|

≤1%

|

>98%

|

>100 S

|

Fully soluble

|

Application of BMI in the field of polymer materials

1. Preparation of thermosetting resin:

BMI can be used as a cross-linking agent or comonomer to react with a variety of thermosetting resins such as phenolic resin, epoxy resin, etc. to form a cross-linked structure. This cross-linked structure can significantly improve the heat resistance, mechanical strength and chemical stability of thermosetting resins. Therefore, BMI-modified thermosetting resins are widely used in aerospace, electronics, automotive and other industrial fields as high-temperature insulation materials, wear-resistant materials, corrosion-resistant materials, etc.

2. Preparation of high-performance fibers:

BMI can also react with polymer fibers such as polyimide, polyamide, etc. to prepare polymer fibers with excellent properties. These fibers have high strength, high modulus, high temperature resistance and good chemical stability, and can be used to prepare high-performance composite materials, protective clothing, sports equipment, etc.

3. Preparation of high temperature coating:

BMI can be used to prepare high-temperature coatings. These coatings have excellent heat resistance, chemical corrosion resistance and abrasion resistance, and are suitable for use in various high temperatures and harsh environments. For example, BMI-modified phenolic resin coatings can be used to prepare high-temperature protective coatings to protect metal surfaces from oxidation and corrosion.

4. Preparation of polymer composite materials:

BMI can also be blended or copolymerized with other polymer materials such as polyimide and polyamide to prepare polymer composite materials with excellent properties. These composite materials combine the advantages of multiple materials and have high strength, high toughness, high temperature resistance and good chemical stability. They can be used in aerospace, automobile manufacturing, electronics and other industrial fields.

5. Development of new polymer materials:

As an important chemical intermediate, BMI's unique structure and properties provide the possibility to develop new polymer materials. Through in-depth study of the reaction mechanism and properties of BMI, polymer materials with better performance can be developed to meet the evolving industrial needs.

Packging

PE bag lined with PE film, net weight 25kg/bag.

Why choose Yangchen Tech?

1.We are the first competent factory manufacturing N,N'-4,4'-diphenylmethane bismaleimide in China, with an annual production capacity of 3000 tons.

2. With over 30 years of industry experience, our expertise shines through in our products.

3. We have served more than 100 customers from all over the world.

4.Our R&D team provides technical solutions and technical support to meet your specific needs.

FAQ

Q1: Is Yangchen Tech a manufacturer or trading company?

A: We are the first BMI manufacturer in China, with an annual production capacity of 300 tons.

Q2: Does Yangchen Tech provide free samples?

A: We are very glad to provide you with free samples for your testing .

Q3: How to pay for the order?

A: We accept payment by T/T, L/C.

Q4: Does Yangchen Tech provide technical support for customers?

A: Yes, we do. Each customer's application is unique in some ways. Our customized services of BMI are designed to better meet your needs. Based on our 30+ years of experience in the rubber additives industry, we can provide technical support services based on your specific needs.

Service Station

Service Station

leave a message

leave a message