what are you looking for?

Popular Searches

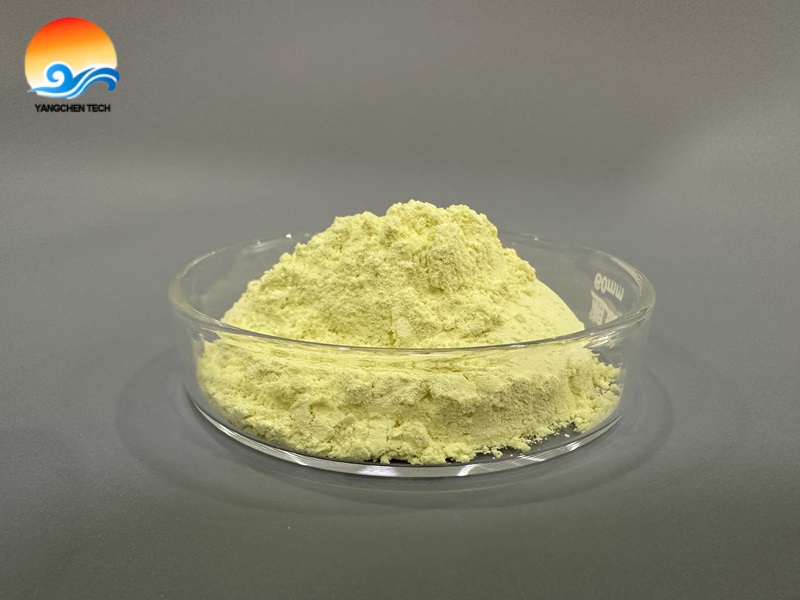

- N-PMI manufacturer

- N-PMI powder manufacturer

- PTNP powder wholesale

- PTNP powder manufacturer

- NAPM powder wholesale

- NAPM powder manufacturer

- BMI-80 powder manufacturer

- BMI-700 powder manufacturer

- Polyimide resin PI-BT

- Polyimide resin PI-BT supplier

- NSA copolymer producer

- Phenylmethane maleimide powder

Service Station

Service Station

leave a message

leave a message