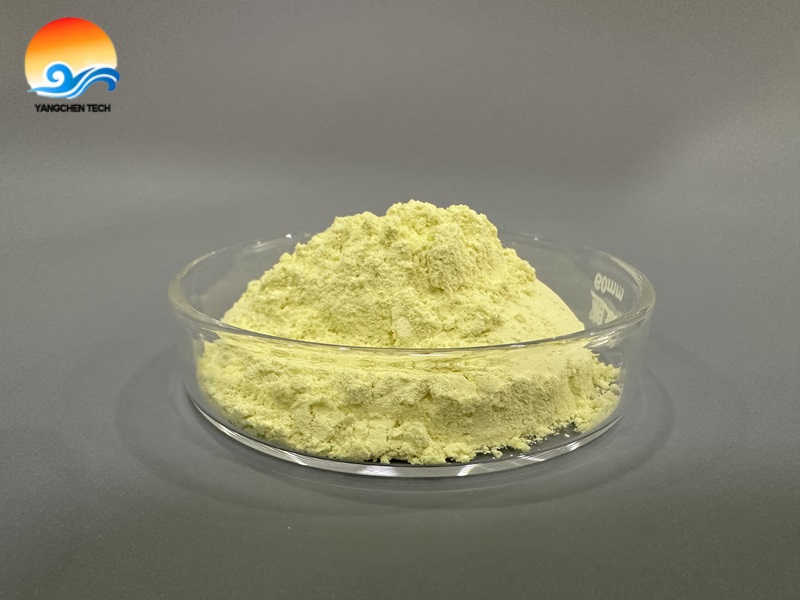

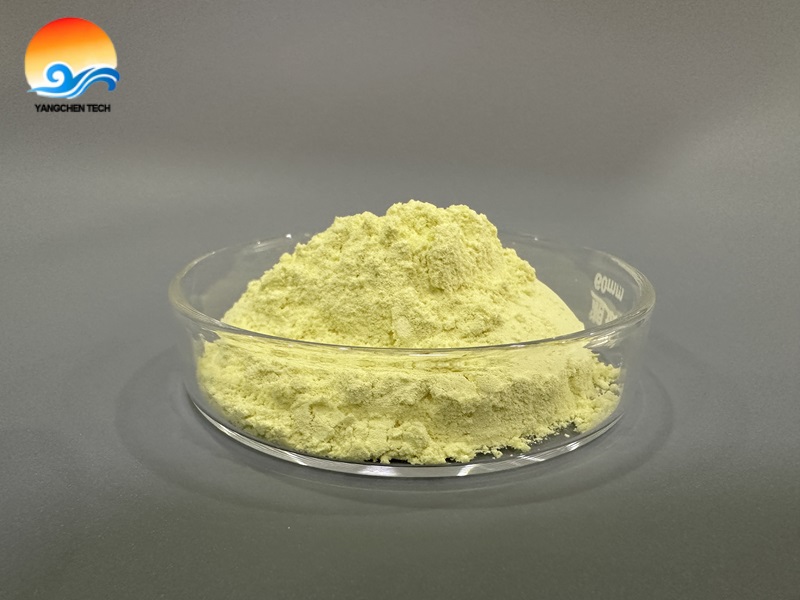

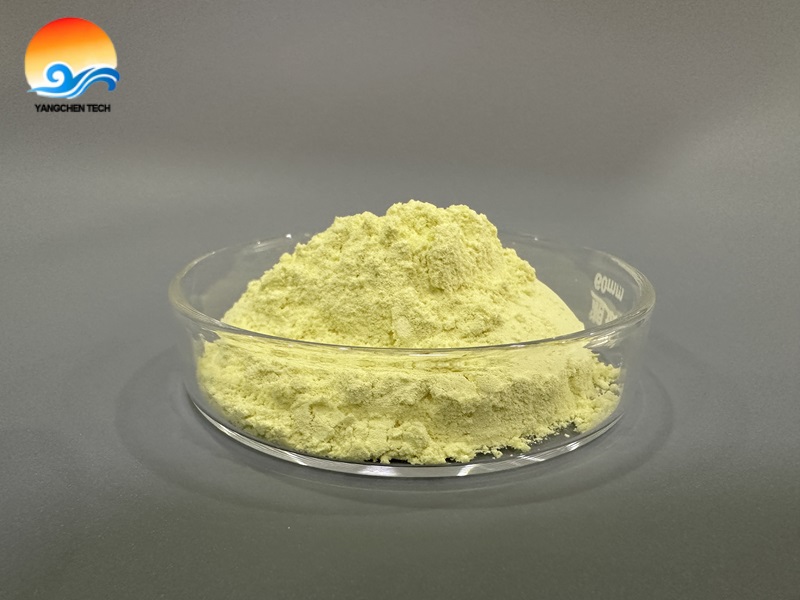

BMI manufactured by Yangchen Tech is an ideal resin matrix widely used in the manufacture of heat-resistant structural materials and Class H or F electrical insulation materials. It is widely used in many industrial fields such as aviation, aerospace, electric power, electronics, computers, communications, automobiles, railways, and construction. Specific applications include:

(1) Motor insulation materials, such as high-temperature resistant impregnating paint, enameled wire paint, laminates, weftless tapes, mica tapes, electronic copper-clad laminates, molded plastics, epoxy modified powder coatings, castings, etc.;

(2) Advanced composite material matrix resin, such as aerospace and aviation structural materials, carbon fiber high-temperature resistant structural parts, high-end printed circuit boards, etc.;

(3) Reinforcement modifiers for engineering plastics, such as polypropylene, nylon, ABS, APC, PVC, PBT, EPDM, PMMA and other materials, which can also be used as cross-linking agents for TPV, new rubber vulcanizers, etc.;

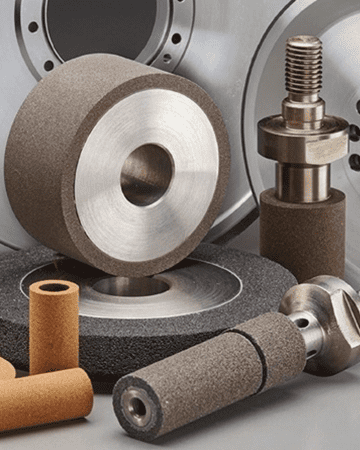

(4) Wear-resistant materials, such as diamond grinding wheels, heavy-duty grinding wheels, brake pads, high-temperature-resistant bearing adhesives, magnetic materials, etc.

Jan 13, 2026

Jan 13, 2026

Service Station

Service Station

leave a message

leave a message